Dr. Kashif Tufail Chaudhary

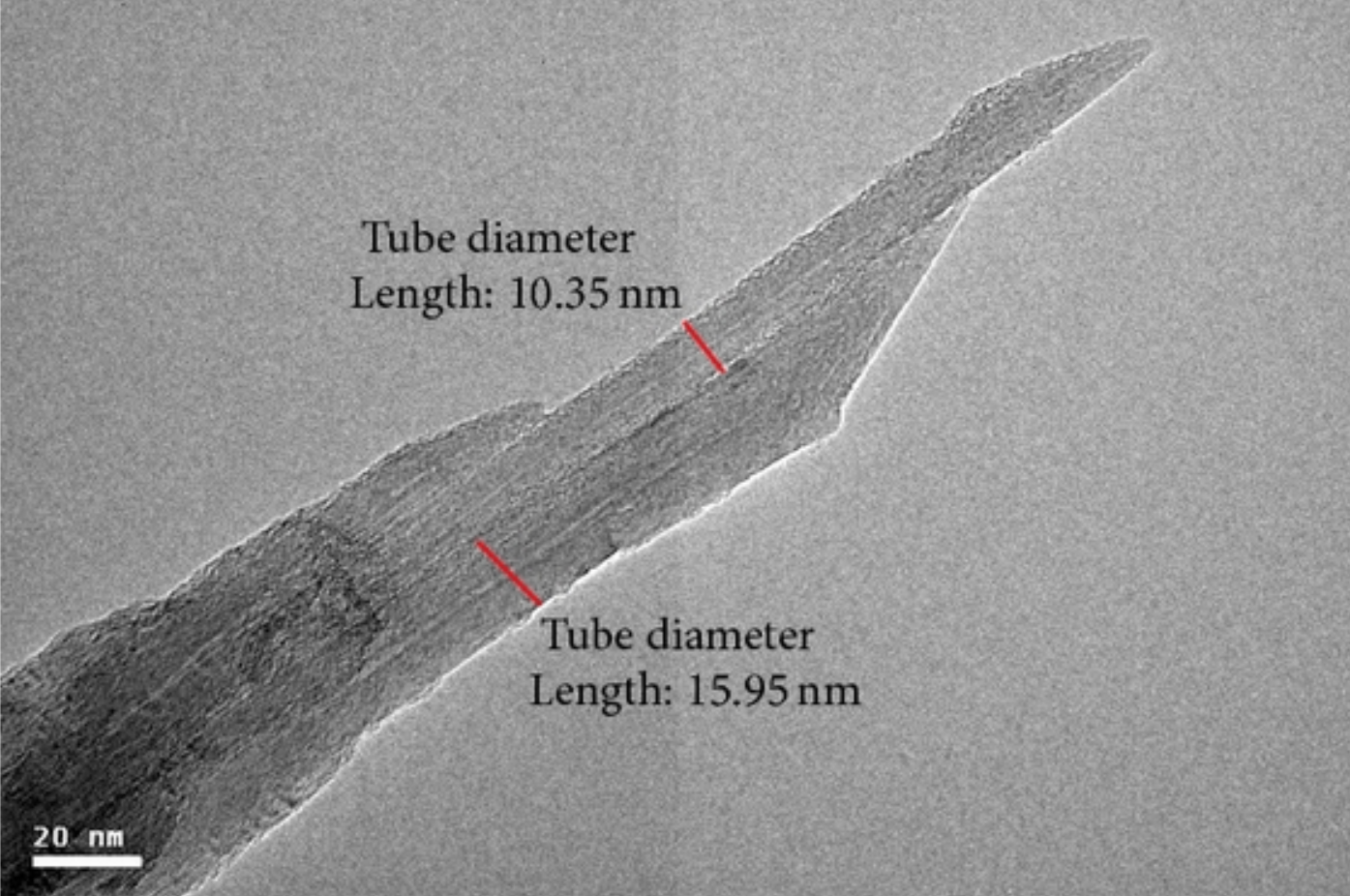

The unique structure of carbon nanotube (CNT) exhibits extraordinary electronic, thermal, and mechanical properties which make them a potential candidate for different technological applications. Extensive efforts have been done to synthesize structured-controlled CNT. Several methods have been developed to synthesize CNT such as arc discharge, chemical vapor deposition (CVD), and laser ablation. Among these methods, the arc discharge method is a promising technique capable to fabricate high-quality CNT. However, the control growth of CNT has not been accomplished due to lack of control and limited understanding of arc discharge plasma. A high influx of plasma species and high temperatures play key role in the growth of nanostructures. In order to realize and optimize the application of CNT, it is desired to understand the growth mechanism and influence of physical parameters (as ambient pressure, electrode geometry, applied current and voltage, gas flow, inter-electrode distance, dynamics of plasma species, etc.) on the growth of nanostructures. The arc current, ambient gas, and ambient pressure are the important parameter for arc discharge synthesis of MWCNT. The arc current supplies energy to anode causing the evaporation of anode surface and formation of arc plasma. The MWCNT with diameters largely distributed in the range of 40–60 nm is observed for an arc discharge in absence of ambient gas. During arc discharge evaporation, the ambient gas acts as buffer gas and influences the growth and diameter distribution of MWCNT. The arc discharge process for the synthesis of MWCNT is studied in different environments to control and improve their growth. For instance, in helium and argon environment the diameter distribution goes higher by varying the gas mixture from argon to helium and an average decrease in diameter is observed with increase in the argon-helium ratio. In liquid nitrogen environment, for low arc current the spherical nanostructures with small diameter while for large arc current the CNT with a large diameter is observed. No cathode deposit is observed during discharge in de-ionized water; a layer of soot appeared at the surface of the water which contains elongated rounded carbon structures such as nano onions with some polyhedron structures and MWCNT [16]. In ammonia environment, no significant difference in the shapes and the structures of CNT is observed [17]. The hydrocarbon gases are widely used to grow the CNT using CVD and plasma-enhanced chemical vapor deposition (PCVD) techniques [18–20]. However, there are not many investigations carried out on the hydrocarbon gases used as background and feedstock gas in the arc discharge process.